Metal & Steel Coatings: Superior Protection for Industrial Applications

Premium Metal Coatings & Steel Protection Systems from Epoxy Central

At Epoxy Central, we specialize in high-performance metal coatings and steel coatings engineered to deliver exceptional durability and protection for industrial applications. Our advanced epoxy metal coatings are designed to resist corrosion, abrasion, and chemical exposure, ensuring your metal surfaces maintain their strength and aesthetic appeal for decades.

Why Choose Professional Metal Coatings for Steel Protection?

Superior Corrosion Resistance

Unprotected steel and metal surfaces are vulnerable to rust, oxidation, and environmental degradation that can compromise structural integrity and appearance. Our professional-grade metal epoxy coatings create an impenetrable barrier that prevents moisture, oxygen, and corrosive substances from reaching the metal substrate. This advanced protection extends the lifespan of steel structures, equipment, and components by decades while maintaining their structural integrity and professional appearance.

Advanced Metal Surface Protection Technology

Our steel coating systems utilize cutting-edge polymer technology that bonds permanently with metal surfaces at the molecular level. Unlike traditional paint systems that simply sit on the surface, our metal epoxy coatings penetrate and chemically bond with the substrate, creating a unified protective system that won't chip, peel, or delaminate under extreme conditions.

Industrial-Grade Chemical Resistance

Manufacturing and industrial environments expose metal surfaces to harsh chemicals, oils, solvents, and cleaning agents that can damage ordinary coatings. Our chemical-resistant metal coatings provide superior protection against:

- Acids and alkalis used in manufacturing processes

- Petroleum products and hydraulic fluids

- Industrial cleaning chemicals and degreasers

- Salt spray and marine environments

- Food acids in processing facilities

- Automotive fluids and chemicals

This comprehensive chemical resistance ensures your metal coating investment provides long-term protection and reduces maintenance costs significantly.

Comprehensive Metal Coating Solutions for Every Application

Metal & Steel Industrial Coating - Aluminum Finish

Our flagship one-component polyurethane steel coating provides exceptional protection for steel and metal surfaces against corrosion, rust, and environmental stressors. This professional-grade metal coating features:

Superior Adhesion Properties: Engineered for excellent adhesion to properly prepared steel surfaces, this coating creates a permanent bond that withstands thermal cycling, vibration, and mechanical stress. Perfect for both new construction and maintenance projects on existing steel structures.

Versatile Application Range: Ideal for protecting steel structures, fences, railings, machinery, equipment, and architectural elements. The attractive aluminum finish provides both protection and aesthetic enhancement for visible steel components.

Easy Application Process: Single-component formulation eliminates mixing errors and simplifies application. Can be applied by brush, roller, or spray methods depending on project requirements and surface geometry.

Environmental Durability: Formulated to withstand UV exposure, temperature extremes, and weather conditions that would degrade ordinary paint systems. Maintains color stability and protective properties for years of reliable service.

Heavy-Duty Non-Skid Metal Epoxy Coating

Designed specifically for high-traffic metal surfaces where safety is paramount, this commercial-grade metal coating provides exceptional durability and slip resistance:

Anti-Slip Safety Performance: Incorporates specialized aggregates that create a secure, non-slip surface even in wet conditions. Ideal for metal walkways, platforms, stairs, and work surfaces where slip hazards could cause injury.

Abrasion-Resistant Formulation: Withstands constant foot traffic, equipment movement, and mechanical wear without losing its protective properties or anti-slip characteristics. Perfect for industrial environments, warehouses, and manufacturing facilities.

Metal-Specific Adhesion: Specially formulated to bond with various metal substrates including steel, aluminum, and iron. Creates a durable coating system that becomes an integral part of the metal surface.

Easy Maintenance: The smooth, seamless finish resists dirt and contamination while remaining easy to clean. Regular maintenance involves simple cleaning protocols that don't require special equipment or harsh chemicals.

Wet Surface Metal Epoxy System

This innovative exterior metal coating addresses one of the most challenging application scenarios - coating metal surfaces in damp or wet conditions:

Moisture-Tolerant Technology: Advanced formulation bonds strongly to metal surfaces even when moisture is present, eliminating the need for extended drying times and weather delays. Ideal for emergency repairs and maintenance in challenging weather conditions.

Superior Water Resistance: Once cured, creates an impermeable barrier that prevents water infiltration and subsequent corrosion. Perfect for marine applications, outdoor equipment, and structures exposed to constant moisture.

Flexible Application Windows: Extends the installation season by allowing application in conditions that would prevent the use of traditional metal coatings. Reduces project delays and allows for year-round maintenance scheduling.

Long-Term Durability: Despite its ability to cure in wet conditions, this system provides exceptional long-term performance equal to or exceeding traditional dry-application metal coatings.

Multi-Layer Steel System Coating

Our most comprehensive metal protection system combines the best of epoxy and polyurethane technology:

Advanced Two-Component System: Features an epoxy mastic primer that provides exceptional adhesion and corrosion resistance, topped with a polyurethane finish coat that delivers superior UV resistance and aesthetic appeal.

Superior Chemical and Moisture Resistance: The dual-layer system provides redundant protection against chemical attack and moisture infiltration. If the topcoat is damaged, the epoxy primer continues to protect the metal substrate.

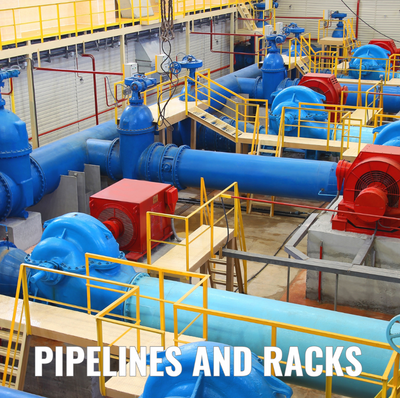

Versatile Steel Applications: Perfect for pipelines, metal buildings, catwalks, bridges, tanks, and other steel structures requiring maximum protection. Suitable for both new construction and refurbishment projects.

Professional and DIY-Friendly: System includes comprehensive instructions and technical support for successful application by both professional contractors and skilled DIY enthusiasts.

Specialized Metal Coating Applications

Industrial Equipment Protection

Manufacturing equipment, machinery, and tools represent significant capital investments that require protection from corrosion, chemical attack, and wear. Our industrial metal coatings provide:

- Extended equipment life and reduced replacement costs

- Improved performance through reduced friction and contamination

- Enhanced safety through improved visibility and slip resistance

- Reduced maintenance requirements and downtime

Structural Steel Coating Systems

Building frameworks, bridges, and structural elements face constant exposure to weather, chemicals, and mechanical stress. Our structural steel coatings offer:

- Long-term corrosion protection that exceeds building code requirements

- Fire-resistant formulations for enhanced safety compliance

- Architectural color options for aesthetic enhancement

- Low-maintenance systems that reduce lifecycle costs

Marine and Offshore Metal Protection

Saltwater environments represent the most challenging conditions for metal protection. Our marine-grade metal coatings provide:

- Superior salt spray resistance exceeding ASTM standards

- Flexibility to accommodate thermal expansion and vessel movement

- Anti-fouling properties that reduce marine growth

- Easy maintenance and repair capabilities for remote locations

Food Processing and Pharmaceutical Metal Coatings

Industries with strict sanitation requirements need specialized metal protection that won't contaminate products. Our food-safe metal coatings offer:

- FDA-compliant formulations for direct and indirect food contact

- Smooth, non-porous surfaces that resist bacterial growth

- Chemical resistance to cleaning and sanitizing agents

- Easy cleaning protocols that support HACCP compliance

Metal Coating Surface Preparation and Application

Critical Surface Preparation for Metal Coatings

Proper surface preparation is essential for long-term metal coating performance. Our technical team provides guidance on:

Mechanical Preparation Methods:

- Sandblasting to achieve optimal surface profile

- Power tool cleaning for maintenance applications

- Chemical etching for complex geometries

- Primer systems for marginally prepared surfaces

Contamination Removal:

- Oil and grease removal protocols

- Salt contamination cleaning procedures

- Previous coating removal techniques

- Surface cleanliness verification methods

Professional Application Techniques

Our metal coating systems can be applied using various methods depending on project requirements:

Spray Application: Ideal for large surfaces and complex geometries. Provides uniform film thickness and professional appearance.

Brush and Roller Methods: Perfect for smaller projects and detail work. Allows for precise application control and economical material usage.

Immersion Coating: Suitable for small parts and components requiring complete coverage including complex internal surfaces.

Quality Control and Performance Testing

We provide comprehensive testing protocols to ensure optimal metal coating performance:

- Adhesion testing to verify proper bonding

- Film thickness measurement for specification compliance

- Holiday detection to identify coating defects

- Accelerated weathering tests for durability validation

Metal Coating Maintenance and Lifecycle Management

Inspection and Maintenance Protocols

Proper maintenance extends metal coating life significantly:

Regular Inspection Schedules:

- Visual assessment of coating condition

- Identification of potential problem areas

- Documentation of coating performance

- Preventive maintenance planning

Repair and Touch-Up Procedures:

- Spot repair techniques for localized damage

- Overcoating procedures for refurbishment

- Compatibility testing for system additions

- Quality assurance for repair work

Lifecycle Cost Analysis

Investing in quality metal coatings provides significant long-term savings:

- Reduced maintenance and repair costs

- Extended asset life and delayed replacement

- Improved operational efficiency and safety

- Enhanced property value and appearance

Environmental Considerations and Compliance

Eco-Friendly Metal Coating Formulations

Epoxy Central is committed to environmental responsibility:

- Low-VOC formulations that exceed EPA requirements

- Solvent-free options for sensitive environments

- Recyclable packaging and sustainable practices

- LEED-compliant systems for green building projects

Regulatory Compliance

Our metal coating systems meet or exceed industry standards:

- OSHA safety requirements for workplace applications

- EPA environmental regulations for emissions

- USDA/FDA standards for food industry applications

- Military specifications for defense applications

Technical Support and Expert Consultation

Comprehensive Technical Assistance

Our metal coating experts provide:

- Product selection guidance based on specific requirements

- Custom formulation development for specialized applications

- Application training and technical support

- Troubleshooting assistance and problem resolution

Professional Installation Network

We work with certified applicators nationwide:

- Qualified contractor referrals in your area

- Training and certification programs for applicators

- Quality assurance support for professional installations

- Warranty programs for approved installations

Advanced Metal Coating Technologies

Nanotechnology Enhancement

Our latest metal coating formulations incorporate nanotechnology for enhanced performance:

- Improved barrier properties at the molecular level

- Self-healing capabilities for minor surface damage

- Enhanced UV resistance and color stability

- Superior hardness and abrasion resistance

Smart Coating Systems

Innovative metal coatings that provide additional functionality:

- Conductive coatings for ESD protection

- Thermal barrier coatings for heat management

- Anti-microbial coatings for sanitary applications

- Color-changing indicators for temperature monitoring

Industries We Serve

Manufacturing and Industrial

- Automotive manufacturing and assembly

- Chemical processing and petrochemical

- Steel production and metal fabrication

- Power generation and utilities

Infrastructure and Construction

- Bridge and highway infrastructure

- Commercial and industrial buildings

- Water treatment and wastewater facilities

- Airport and transportation hubs

Marine and Offshore

- Commercial shipping and naval vessels

- Offshore oil and gas platforms

- Marina and waterfront facilities

- Coastal infrastructure protection

Specialty Applications

- Food and beverage processing

- Pharmaceutical and biotechnology

- Electronics and telecommunications

- Aerospace and defense contractors

Why Choose Epoxy Central for Metal Coatings?

Proven Performance Record

With decades of experience in metal protection, Epoxy Central has established a reputation for:

- Consistently superior product quality and performance

- Innovative solutions for challenging applications

- Comprehensive technical support and customer service

- Competitive pricing with exceptional value

Commitment to Innovation

We continuously invest in research and development to provide:

- Advanced formulations that exceed industry standards

- Sustainable and environmentally responsible products

- Custom solutions for unique application requirements

- Next-generation technologies for enhanced performance

Customer-Focused Service

Our commitment to customer success includes:

- Responsive technical support and problem-solving

- Flexible ordering and delivery options

- Training and education resources

- Long-term partnership approach to customer relationships

Contact Epoxy Central today to discuss your metal coating and steel protection requirements. Our technical experts are ready to help you select the optimal coating system for your specific application, ensuring long-term protection, performance, and value for your metal assets.